2022

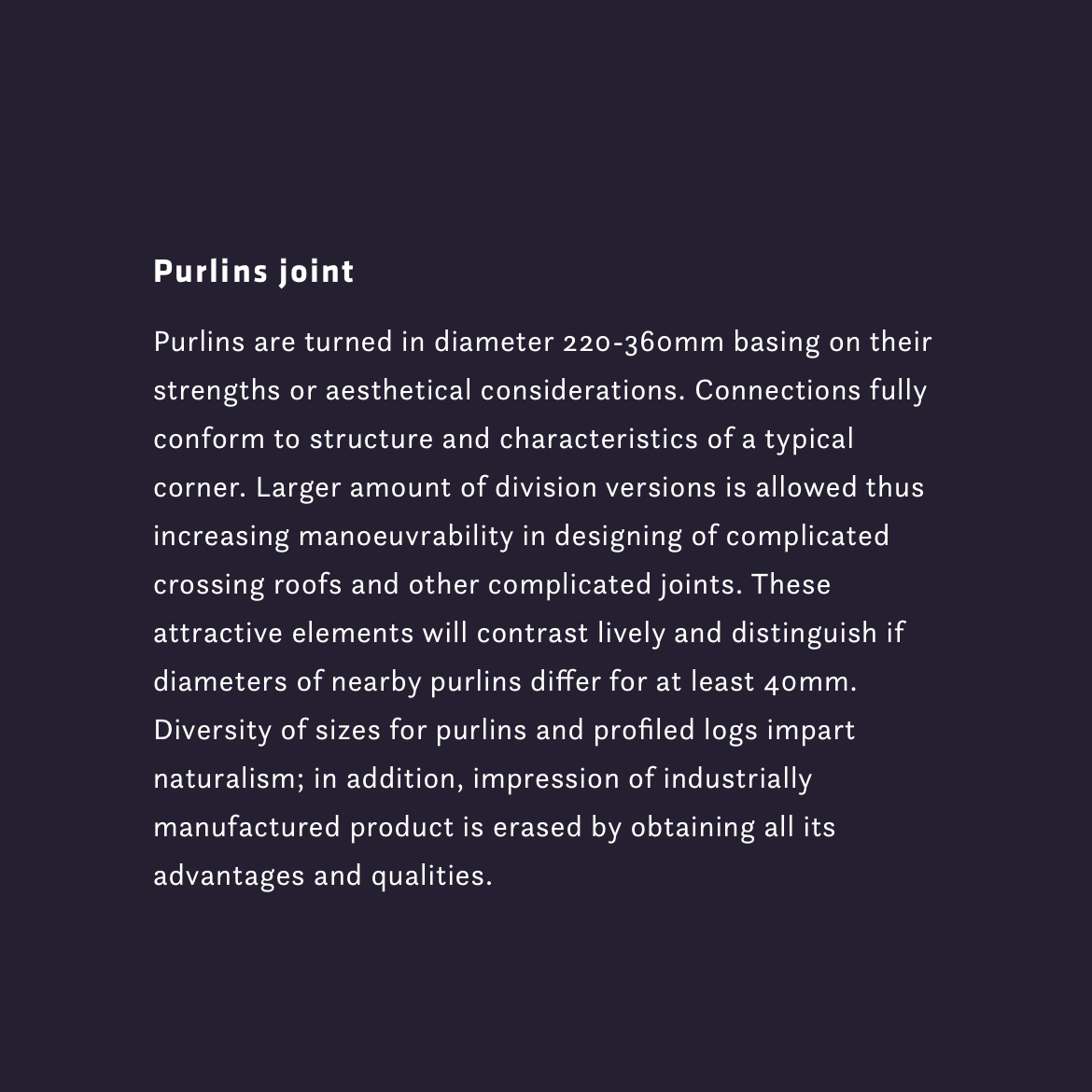

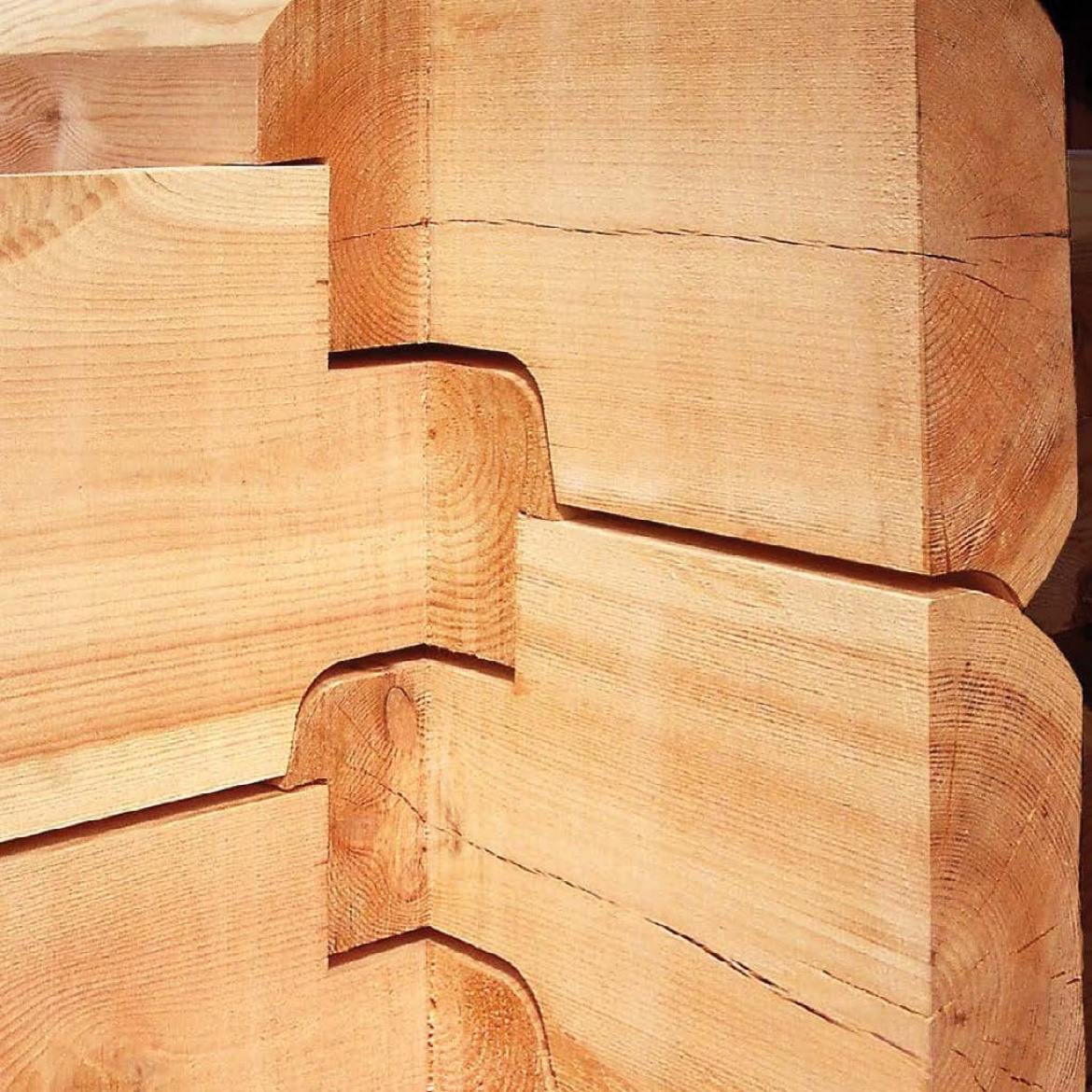

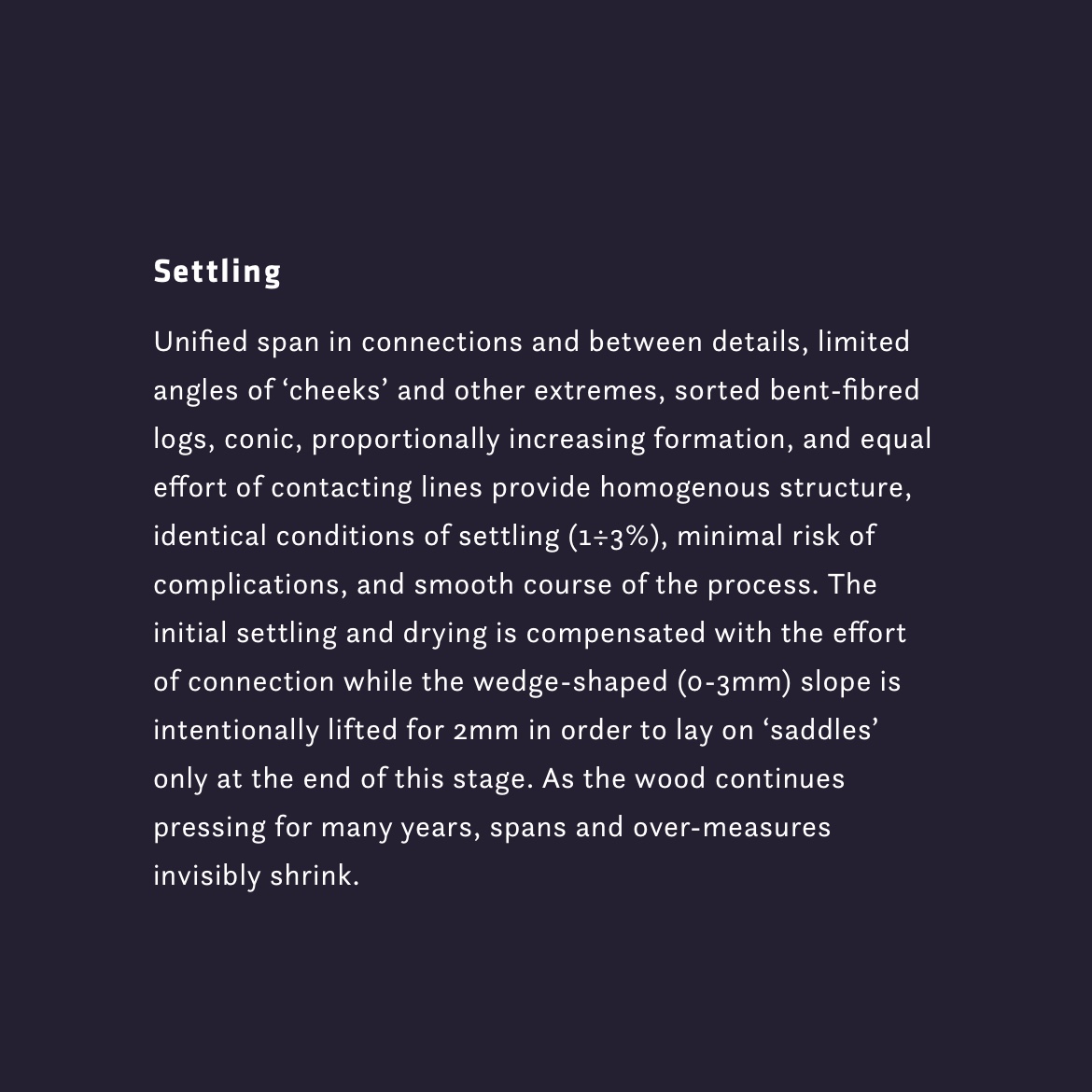

The year is crazier than all the previous ones. All kinds of difficulties and aggression of Russia. First, it “invent” an export duty of 200 €/m³ for beams, then unleash a war in Ukraine. The result was the liquidation of OOO LETTA after 19 years of a hopeless fight. The year offers a log price frenzy, a multiple increase in the price of electricity, an increase in ECB credit %, inflation, and very tough fights with bureaucrats. We hand over both EU projects only with great difficulty... We combine the legal and production address: Celtniecibas street 26, Livani. LHM Gruppen returns to the circle of customers, and new customers from Norway and Sweden appear. Probably because of the sanctions and the lack of cheap, semi-legal log cabins from Russia. In total, we produce 33 log houses. Photo: Manufactured log details with original log profile.

![]()

2021

This year begins with a new production manager and a comprehensive arrangement. The interest of customers is renewed and the development of the company continues. In April, we finally start the construction of the boiler house. Additional costs 1.7M. EU co-financed yet very bureaucratic project. In order to create a B2C oriented log house brand in Scandinavia, production requires lots of heat energy! The previous B2B model can no longer be relied upon. Dramatic and chaotic year - aggressive prices of logs and energy resources, lots of additional loans, crisis of raw materials and employees. Celebrating a decade of drying research, a partial victory, currently just over the sapwood. It’s clear that we have to fight also for a heartwood next year. Photo: Construction of a 5.3 MW boiler house in Livani, Celtniecibas street 26.

![]()

2020

A seemingly calm wintertime with no new surprises and/or problems. But March is a complete disaster. Internal disbelief and a feeling of betrayal, external shocks, the fall of the Norwegian kroner by 30%, etc. Just only after four months of COVID-19 idle standing time do the B2B partners gradually return, because it is better to live without profit than to go bankrupt! We begin cooperation with AS Sjoalaft og Restaurering at the right time. AS Fundament Gruppen finally gets building permits. Even AS Østlaft Bygg is unable to start their own production order for a house or two. We start producing glued laminated timber houses and even railway fencing to survive. We only produce 14 log houses and 5 glued timber houses. We “eat up” our stock of raw materials almost entirely. Photo: Assembly of ‘chalets’ made from glued beams in Fageråsen, Norway.

![]()

2019

We replace the windows in the plant's facades, buy boiler equipment and electricity generators. We develop cooperation with AS Fundament Gruppen, but the number of orders continues to decrease. AS Østlaft and others - only 28 log houses. We cannot understand why until the announcement from AS Østlaft. For 5 years they have been secretly building their own plant by copying our product. Cooperation that has lasted for 20 years ends! It is hard. Also the laboratory work that lasted for 4 years ends in October, in a fiasco. Main benefit is the experience we have gained from various experiments: boiling (the closest to victory) and freezing, chemical, electrical, mechanical and natural treatment, cyclical and combined. The last hope in terms of research is the open-air “laboratory”. Photo: Development of decorative roof trusses at factory.

![]()

2018

Customers from the Swedish mountain resorts are also active. This year 36 log houses are produced as well as the last order from AS Laftekompaniet. This company do not wish to weaken their manual labour plant in Estonia that they have invested so much in. We work on the plans, perform estimates and energy audits until we are able to obtain co-financing from the EU for our heat plant equipment. The total costs of the project amount to 2.5M. We join the Latgale Special Economic Zone to get tax benefits. We pour the foundations for the demo log house (will be used as redrawing office for log house production). We install numerous overhead cranes, we buy a chip crusher and chip transporters, we replace roof windows etc. This is a year of major investments. Photo: Log house complex in Sweden, in the ski resort Idrejfjäll.

![]()

2017

Regardless of the fact that we deliver 32 log houses in total, we are forced to “juggle and survive” once again during the winter months. We attempt to collaborate with AS LHM Gruppen, but the company turns out to be too aggressive. We make a major investment in roof repairs, membrane and its application. In April we settle the last of our credit obligations and have to decide: What direction to take in the future? Development cannot be avoided and we start designing a 5MW heat plant in June, since we plan to increase the B2B manufacturing volume. We pay in advance for the main boiler equipment (from Denmark, Germany and the USA) before Christmas to get it at a more advantageous price. Still no results at the raw material base in Russia and in the drying “laboratory”. Photo: Assemblers of the log house village have a rest. Hovden, Norway.

![]()

2016

In May, under an aggressive schedule, finally we make the last payment to repay the Livani property loan. Income from manufacturing is mainly used to pay for the second attempt at roof repairs, all potential profit is accrued as the stock of raw materials. This year special attention is paid to our Russian subsidiary undertaking OOO LETTA, we complete the installation of the sawmill, debarking machine and crane runway girder. Our aim is to finally implement the supply of pine logs, but unfortunately it does not come to fruition once again. All efforts in Russia usually get stuck. It's like a bog. All in all the year is rather boring, except for hyperactive, hopeful drying tests and the delivery of 40 log houses to all market leaders in Norway. Photo: Russian customs are always looking for and “finding” flaws. Almost hopeless system.

![]()

2015

As part of the company reorganization we merge the log house designing and programming company SIA Artlogs. Finally, we cease settlements in Norwegian kroner to replace them with the Euro payments. At last we achieve the automation of CNC machine, thus eliminating human error completely. We produce and export 43 log houses to Norway. AS Østlaft Bygg wishes to create a joint venture AS Laftebygg Norge, but we cannot agree to such a one-sided and disadvantageous offers. Experiments in wood drying kilns that have lasted four years end in crushed hopes. It is clear that the wood must be pre-treated in some way and the search for a solution must continue. It will continue as practical work in a modern kitchen, it is theoretically like in a laboratory. Photo: Regular control assembly of every log frame at Livani factory.

![]()

2014

We are still forced to export in Norwegian kroner, in spite of the fact that Latvia has joined a less volatile environment - the euro zone. The event reflects favourably on our business and the volume of orders reaches 45 log houses. AS Østlaft Bygg wishes to renew its exclusive status, but their promises are so empty and it all comes to nothing. We plan roof repairs, buy membrane and heat insulation materials, we pay our loans and loans from former founders. In addition to this we design log houses with valuable millings and we begin automation of the CNC machine. We test cycling, sensitivity, self-regulation of drying, condensation of moisture and other methods around the wood drying process. We join the town of Livani with the new address: 26 Celtniecibas street. Photo: Yet another exhibit of our log house at Exporama in Norway.

![]()

2013

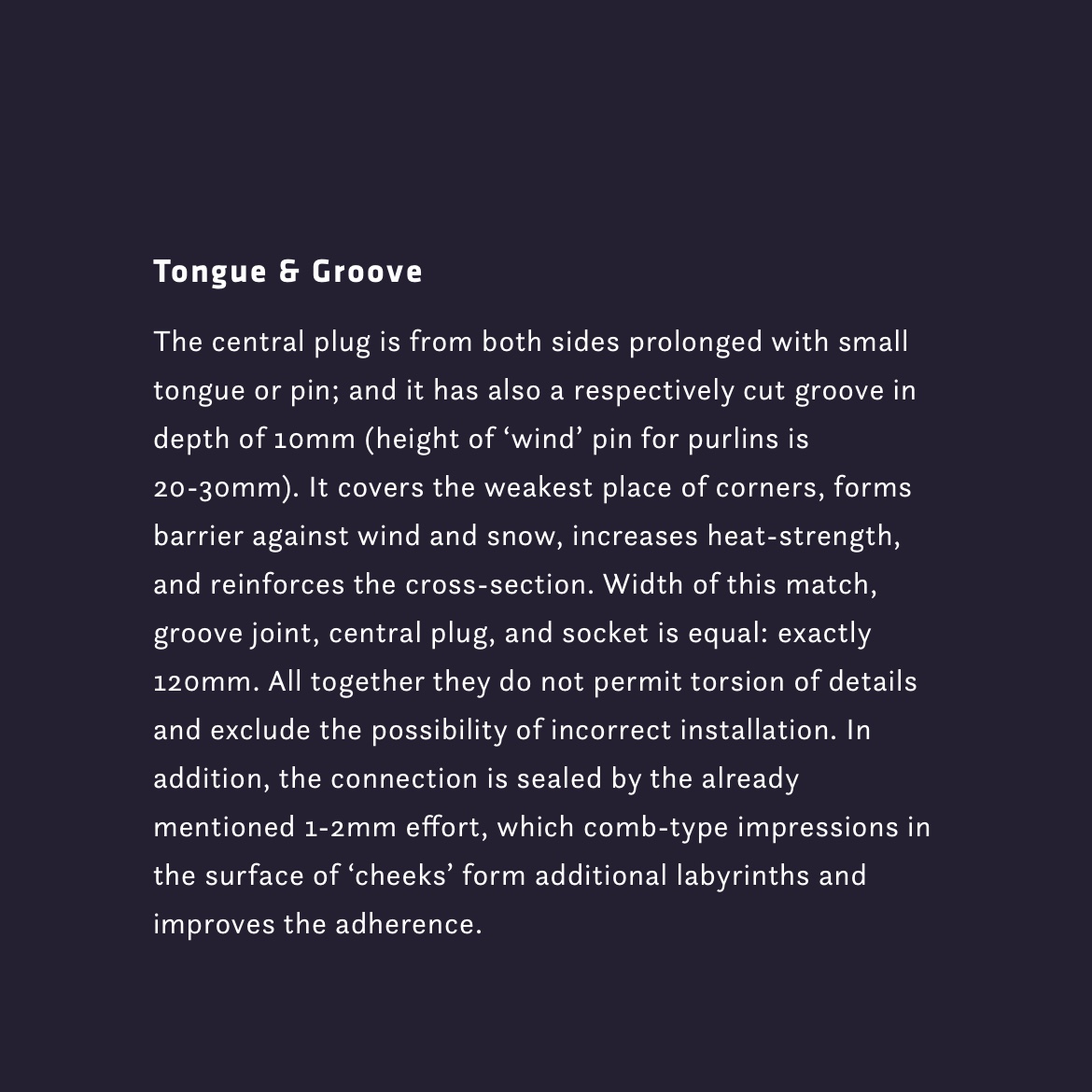

We continue settling in the Livani plant. There is a lot to do in various directions of activity. Hyperactive drying tests, construction of a sawmill in OOO Letta (Russia), removing debris from the roof disaster etc. Now the roof has even more holes and water damages everything very badly. A solution would be membrane melting, but money and time is needed to do that. We are repaying previous loans on an aggressive schedule, but we need new loans too. We have to pull ourselves together and act more energetically. For sure, our product is very good! At the exhibition show we are able to attract a new buyer, another market leader AS Laftekompaniet. So together with our other B2B customers we are able to repeat the performance of the last year – export of 36 log houses. Photo: Our logo is based on the following roof support element.

![]()

2012

The beginning of the year is rich in events. On 20 February we transfer our property in Malpils to BV Lugarde and must leave the premises completely by July. On 24 February the roof of the Livani plant, 80% of which has been reconstructed, fails under the huge snow load. We lose 450000 euros in a flash, because the engineer made a serious error in the calculations of roof restraint straps. On 14 March we terminate the agreement with our long-term exclusive dealer in Norway AS Østlaft (since 2005) because of regularly violating volumes. In May we send a demo log house for the all-season show village in Sweden to our representative AB Siberian Conifers. AS Hovinlaft continues to demonstrate excellent performance. With other B2B buyers we export 36 log houses. Photo: Sample log house in the exhibition village Norsborg, Sweden.

![]()

2011

Under the circumstances of destructive pressure we offer shares of the enterprise to AS Østlaft and even to russians, but it is hopeless. Problems with the founders are finally resolved when the plant in Malpils is bought by the producer of houses BV Lugarde from Netherlands. There is enough money to redeem the shares, but the price of freedom is enormous. We sacrifice numerous machines, the invested work and production must be moved to Livani. To strengthen enthusiasm and loyalty we give shares to our main staff members. We start collaborating with a new partner AS Hovinlaft and together we produce 40 log houses. The director undertakes the fight of the decade. Hoping to radically improve the quality of log drying, he starts testing resonance waves technology. Photo: The initiator of experiments on wood drying Valery Yurdanov from Russia.

![]()

2010

Economic activity is resuming and production volumes increase, but troubles with founders are brewing. They wish to sell their shares, solution is needed. Regrettably the total amount of loans exceeds 1M and the bank has taken everything it could as collateral: buildings, land, machines, property and even shares. It is clear that the enterprise has to get rid of this group of founders and the fuss will settle down. In the meantime we continue clearing the Livani plant and are building a roof over the existing one, finishing construction of the shelter in Malpils, constructing a 3rd generation CNC machine. We agree on the supply of logs from PLC “Valsts Mezi”, the largest enterprise in the country. We are able to introduce a special assortment item, with the top end 32 cm and up, and with higher quality requirements. Photo: Making CNC milling equipment in Livani.

![]()

2009

Difficulties are made worse by the unprecedented fall of the Norwegian krone. Minus 26% compared to its value in 2007. Unfortunately, we have to complete the concluded agreements for a fixed price. The annual spring building show is half-empty, our official representative is almost alone there. The leader of the industry, because 2/3 of craft-based enterprises have already fallen victim to the crisis. The number of employees diminishes to 20, as well as the number of houses produced. Orders from the Netherlands make up for the crisis in Norway. However, at last the time has come to find a solution for the log house roof girder joints. The result is excellent, without defects! CNC mills corner joints in the walls, carpenters form the “cheeks” of the round logs using special templets. Photo: Assembly of log building complex - Boekel, Netherlands.

![]()

2008

We are hit hard by the global financial crisis, but we survive. We are saved by the momentum of agreements concluded earlier. In spite of everything AS Østlaft even opens the log house office began at the beginning of the year. However, hopes of many enterprises are crushed, including SibirLaft. The Norwegian tax inspectorate exerts power, brutally collecting VAT. Namely, the customer burns his documents and goes bankrupt, but the defrauded VAT is claimed from us. Agency that administers EU funds also goes on a rampage. Unable to get a bribe, the officials take revenge. They torpedo the sawmill project and play a part in the failure of the “Construction of a CNC Machine” project supported by another agency. Institutions do not even consider complaints submitted by lawyers, they ignore them. Photo: Dealer's team in a log house - Rudshøgda, Norway.

![]()

2007

We produce 70 log houses, all of them by means of CNC. It is too crowded in Malpils! We build a 1000 m² shelter, because the premises in Livani must still be cleared and we are not yet ready for roof repairs. AS Østlaft becomes the leader of the log building industry and us - the largest supplier of frames. The total number of employees of our enterprise and subsidiaries (Artlogs and Letta) reaches 72. Sales converted into euros amount to 3.5M. Orders also come from Sweden and the Netherlands, 3 and 4 log houses respectively. OOO Letta continues supplying larch from Siberia. Log houses made of larch are sold together with AS SibirLaft. In November the two most diligent workers get involved in the assembly business, launching SIA Eko Partner (later AS LCB). Photo: Larch log house assemblers at the exhibition Varemesse, Norway.

![]()

2006

We must buy it! With our sight fixed on the future we get a loan and this property, a part of the USSR house building factory, becomes ours. It is the deal of the century, it comes with equipment that can be used in the manufacture of log buildings: cranes, a heating boiler, a wood drying kiln, woodworking machines. Premises must be cleaned and repairs of the roof must begin, windows need to be replaced and equipment must be restored. We are not in a hurry yet, since the epicenter of events is in Malpils. There, by means of co-financing from the EU, we start building the second, next generation CNC machine. The number of orders increases, we produce 50 log houses. In the meantime Norwegian tax and labor inspectorates pile up bureaucratic obstacles. It would be safer to separate production from assembling. Photo: Director at the vast premises of Livani.

![]()

2005

By continuing the development of the log house extension to Archicad software, we purchase SIA Artlogs. Log build designs with logs of different heights must be elaborated in greater detail, millings, drillholes, all types of corner joints, apertures etc. must be introduced. All in the name of product quality and to receive additional co-financing from the EU. We put up 46 log houses in Norway. Most of them are already produced using the CNC machine. The quality of manual work involved is wanting and it provides motivation to improve the machines faster still. At the end of the year we sell our base in Vangazi, but the received money is used up quickly. Malpils plant is getting too small and as a solution for the future, fate throws a plant in Livani our way. 28 000 m² under a roof. Photo: Log house made of Siberian larch - Kvamskogen, Norway.

![]()

2004

27 log houses successfully built. All of them are handmade in Vangazi, except for the first order of the new product. Malpils plant is buzzing with activity: the first CNC machine has to be launched, a profiling machine must be installed, the heat plant, wood chip storage, transporters of half-finished products, the office etc. must be set up. Two wood drying kilns must be installed too, this time fully equipped. Latvia accedes to the European Union and the enterprise is able to attract SAPARD co-financing. We invest all available money, live hand-to-mouth, because it is very important to get on our feet now. Chaotic haggling with buyers (about the price of each framework of a log building) is replaced by an objective calculation of the area (m²) of log structures. Photo: Our programmer Mr. Girts Gaidels is very deep in thoughts again...

![]()

2003

We welcome new members to our team – experts in programming and mechanical engineering. We decide to develop CNC machine & technology to substitute manual labour. We purchase a 4000 m² premises. It is a former vegetable warehouse at 6 Kirsu street in Malpils that must be adapted for manufacturing purposes. We convince AS Østlaft to take the risk and announce the new product, and book a stand at the show in Oslo. At the last moment our improvised machine is able to mill corner joints with provisional cutting trajectories for a manually designed house. The presentation is a success! Future plans are ambitious! To be on the safe side we hurry and establish a log supply company in Russia. In the meantime we continue “manufacturing” of handmade log houses, because we need to live on something. Photo: Interest of customers at Exporama, Norway.

![]()

2002

With the great determination we install a wood drying kiln (only the basic components were bought) in one of the garages and the neighbouring box is converted into a heat plant. This is done according to our rather limited financial means. Quality requirements are growing, namely, log houses made of green (wet) wood can no longer be exported and the new standard of the industry sets forth that the moisture content of the wood at the time of delivery may not exceed 18%. Thus we are able to prove our competitiveness and not lose orders our partners have organised for us. We complete orders on time, make and assemble 13 handmade log houses. We develop communication with construction companies, identify all the difficulties, errors and settling nuances of buildings. Photo: Survey on the first logs dried by kiln.

![]()

2001

Log houses orders from Trysil (Norway) ski resort follow. We strengthen our reputation as a reliable partner, gather experience and knowledge. We become sound subcontractors and deliver log houses on time until SIA “Dzintara Laivas un Majas” withdraws its assembly team. We do what we can to remedy the situation and get work permits urgently. This is how cooperation with a local partner AS Solvang Byggprosjekt, later AS Østlaft, starts. Logical and mutually advantageous cooperation without unnecessary middlemen, the driving force of our sustainable growth. The bank grants a loan for the purchase of a 1600 m² premises at 24/8 Gaujas street in Vangazi. We start adapting garages from the Soviet times, install lifting equipment, and acquire special axes and drawknives. Photo: Activity of carpenters at the Vangazhi workshop.

![]()

2000

Founding of the enterprise on 11 February and beginning of all operations immediately thereafter. After renting an 800 m² garage at 20/22 Udens street in Riga, the director of the enterprise adapts it for the needs of production and starts sharing his experience. He works actively and trains personnel, often even at night. While the first log houses are built, he organises negotiations with the Latvian-Norwegian joint venture SIA DLM. He encourages the young craftsmen and proves that they can be entrusted with the production of any log building and achieves a positive decision. The first Norwegian order is erected in Valdres region. The fateful debut is a success and the owner is very enthusiastic. It means that the carpenters are doing their job well, the purchase of logs must continue. Photo: Log house to the first norwegian customer – Blilie, near Fagernes.

![]()

In the Latvia University of Life Sciences and Technologies Ervins Poga developed a unique, self-illustrated graduate work “Construction of Log Buildings”, with detailed instructions for how to process logs and make log corner joints (norwegian). You can see illustrations as decorative element in the openings of our brochure. The purpose of creating these instructions was to use them to train employees in a company of his own creation. The company SIA "Log Art" was established in 1997, and it had been successfully operating for 3 years. It was useful for gaining experience, teaching employees and other type of "training". One log house was even sent to Lübeck, Germany - see photo. The all-encompassing short-sightedness and lack of involvement of the other founders was leading Mr. Poga to withdraw from this “log art” company.

![]()