In principle, anyone living in Norway and interested in log houses can easily conclude that this market is mainly supplied by producers or manufacturers from the Baltic and other Eastern European countries. Moreover, the leading part of the supplied houses is, or are marketed as, constructed using hand-work. It is true that, unfortunately, in most cases this means a “modern” version of hand-work — a highly theoretical hand-work.

There is no doubt that a primitive mechanization, an accelerated and simplified treatment process, an otherwise rushed execution is negatively reflected in the product’s overall image, and, as can be witnessed in real life, the performance achieved through such methods and with rush, however, cannot ensure fundamental qualities and, let alone, dream of corresponding to the spirit of hand-work. It cannot be denied that these producers or manufacturers have succeeded in creating a peculiar derivative or hand-work, a modern version or a temporary solution; but only for the sake of clarity it should be noted that similar versions of hand-work should be further clarified, for example, by using the comment — the so-called, relative, partial, sort of and so on. Actually, in 99% of cases the manufacturers’ comments regarding and references to “hand-work” can safely be placed in quotation marks, because there has been nothing unique or exclusive there for a very long time. Nothing made by hand… But what exactly is in there, in short?

On the one hand – an incorrect, imprecise and incomplete imitation of old hand-work practices and traditions, clumsily executed mechanical treatment, as well as countless product qualities that do not meet modern requirements – on the other hand. Excuse me, neither this nor that, no traditions, no development, something unnecessary, something in the middle.

Photo from the history of the Log Art company, i.e. 3 years before the founding of LLC Eko Nams in 2000. Painful memories of hardship come to mind. After you’ve endured the brunt of hand-work problems…

But it is hand-work, as they seem to claim. Armed with this title, both various underground craft masters and individuals looking for some easy money can much easily foist off their amateurishly constructed log house on to you, because the tag “handmade” still has an effect on people; so far it amazingly helps everyone. It truly is unbelievably convenient — so much can be written off at its expense. It is capable of both justifying defective goods and clouding over grave mistakes and a lack of knowledge. It can significantly increase the price and even affect competitiveness. Yes, but what would the buyer of such an exclusive, meaning, uselessly expensive, log house see if he visited the production area of this so-called “producer”? A barn harried apart by draught, a band saw covered in wood chips, a pile of run-down electric tools, a mess of mended and sparking wires. And are there some gray faces looming deeper in the darkness among the smoke? Yes, the figures, hunched over for only a moment, stiffen upon being disturbed… but then, once again, they rush to feverishly make themselves busy again, these rulers of growling chainsaws. Alright, let us set aside the contradictions and contrasts of the modern world.

Of course, it has long been clear to everyone that the situation would greatly improve if only specifically certified companies and craft masters were allowed to say that they offer hand-work services. But it is extremely naïve to hope that some kind of certification institution will ever be established for this industry, a cross-border one at that, one that has sufficient knowledgeable, one that is influential and strict enough. It truly sounds unbelievable. And who will be the one to commit to realizing and creating something like that? But how else can the degradation of this form of craftsmanship be stopped?

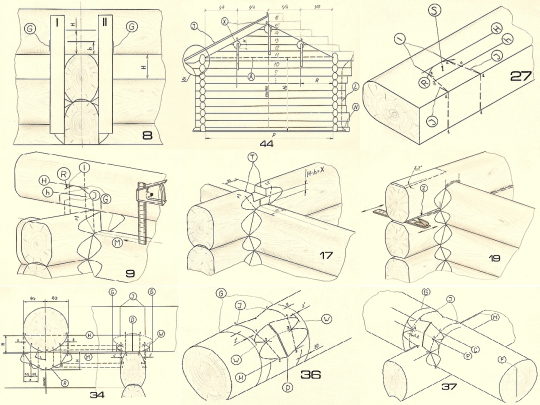

Typical, modern hand-made corner joints. Too often this leads one to think about wasted material, about the pointlessness of such work.

Of course, an incomparably easier or simpler solution is to push all these (or only such) log houses out of the market in general, for example, by officially increasing the norms of thermal resistance or air permeability of buildings. In other words, prohibit their construction, prohibit it by law. Yes, of course, it is an extremely brutal and also an irresponsible solution, but that would finally make it possible to put a definitive end to this whole mess. And as you probably know, a similar assassination attempt was even planned and organised in Norway very recently — in 2015. At that time, such a solution or a cul-de-sac was proposed instead of confronting all quality-related challenges, instead of trying to sort out these problems and issues related to the construction of log houses. Thank God that the new “improvements” of construction regulations could not be introduced at that time, since they faced too much of a serious opposition from the companies of this industry. However, this does not mean that the fundamental threat has been eradicated this easily — as we know, the highly esteemed legislators have simply mercifully moved the re-assessment of this issue to a later, to unknown time.

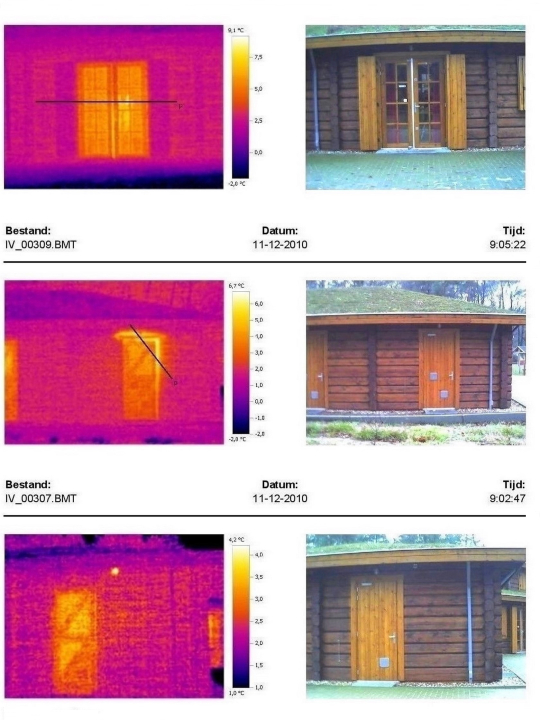

Such an icicles are evidence of roof insulation problems. For your information, heat loss through the walls of a log house ranks 3rd, behind windows and front doors.

However, how short-sighted and inadequate the approach is at its root. By waging war against any kind of creative activity, it will contribute even more to the degradation and suffering of humanity. And another national treasure will be irreversibly lost; therefore, the degradation of culture and knowledge will be able to continue its conquest. But are we giving up already? Shall we keep watching soap operas, eating processed food and living in an airless environment, in plasterboard boxes or in passive houses? Perhaps let us print out plastic huts with no windows at all, perhaps let us move to an artificially inseminated life in a thermos? Alright, perhaps it is enough of exaggerating for once, enough of making mistakes.

It is time to return to the topic we began with, namely, to the analysis of the situation regarding log houses constructed using “hand-work”. So, what is the situation like regarding this niche product in neighboring countries, in other parts of Scandinavia? Buyers in Sweden choose these forced “hand-work” log houses incomparably less often, but Finland chooses to not deal and struggle with them if possible or chooses to not deal with them at all. Finland has long forgotten about authentic log houses, and almost all traditions and knowledge of the old days have been swept away there. The situation there is, to put it mildly, hopeless. But this is happening in the empire of industrial production of log houses! It is true that, as we have already started to explain, this mass production does not correspond to or corresponds only relatively to the sector of log houses.

In other words, interest in hand-work in neighboring countries is extremely low because it seems that it is not enough to use only some client-motivating factors; it seems that it is necessary to use more extensive and more strongly motivating factors. All the possible array — quality, price, health, functionality, service, modernity, warranties and so on. Perhaps, buyers also possess a different mentality, perhaps they have a colder demeanor and are more pragmatic, perhaps, the purchasing capacity is also at fault. It is clear that the modern buyer, even though he is for a healthy living environment, will not pay extra just because of that. And for the client to do some repair work or install some additions to the log house? To overpay and to then have to screw in something by yourself, to have to adjust something, to later have to solve the various settling problems of a log house and to deal with cracks? Somehow no one wants to deal with puttying cracks, especially on their holiday.

A happy customer of EKO NAMS LLC, in a Siberian larch log house.

Let the “hand-work” ideologists scratch their heads, let them consider the current state of the industry, because it is far from simple and it never has been. But they will be left with nothing else to do except to accept the severity of constructive criticism, and they will be forced to take into account the challenges of today’s world, they will have to contemplate the influence of objective factors, justify it somehow and explain the viability of this product. The sustainability of this industry must be viewed much more skeptically — from an economical, practical, tactical point of view and in relation to all sorts of other things. Everything should be reviewed, but, on the other hand, it is no pressing matter — everything can be left as it is, no new inventions and no retortions, one can do nothing about it while there is still the option to do nothing. Simply settle back into the chair.

Log house in Sweden, hand-hewn in the 2nd half of the 20th century. Dalaknut corner joints. It seems that the craftsmen did not exert themselves too much, they overshadowed the accuracy and quality with a harsh and robust image.

And another handmade log house – another illustration of the nightmares of corner joints, log shapes, grooves, butt ends, etc.

To be honest, we doubt that a passionate defender of the log house industry will surface who will be able to disperse these looming clouds, as this requires a consensus among all the parties involved. And no matter how different subjective opinions might be, it is necessary to bring clarity to a situation where there is no longer room for idle talk and mesmerizing visions of what the future might be. So will we see defeat or will this “someone” present a truly implementable plan of action? And then, will a determined action really follow after this or will simply a presentation of some grand plan work? You have to take off properly, don’t you? But is there anything to take off from if you look at it from a practical point of view? Does some kind of support exist, is there any real foundation? Will a somewhat sensible justification for the viability of such “hand-work” present itself? And above all, being able to do something is proved with deeds and not by words.

All right, we will see that in the future. But why do the Norwegian people need the hand-work so much?

Because such log houses, even in spite of the overall severity of the defects, are still something very special, as respect for old traditions is rooted so deeply in Norwegians. Because it is also a matter of fashion, prestige and even national identity, because it is simply a fact that Norway is witnessing a log house renaissance. Because such log houses include both classic values and an expressive style, since their charm, naturalness, coziness and, of course, healthiness are beyond doubt. In addition, log houses are an ideal component for enthusiasts of active lifestyle; three or four into one. So, marketing specialists currently have no difficulty in finding the “strings” by which to pull the buyers; they only have to play their cards right. And not without reason for many Norwegians log houses are also a hobby and their passion, a creative and physical activity, a means of enjoying a pleasant time. They can build a house with no rush, simply for their own pleasure, caress every little log, truly feel joy for what they have accomplished and for the time spent sensibly and healthily. By the way, such work is also completed quite knowledgeably and correctly, as to say, “with using one’s head”, and it is about these masterpieces made by amateurs that you could say that the work has been completed using “hand-work”. With all due respect, because the result is incomparably better than the so-called hand-work companies can show. However, let us not confuse emotion, the hobby and professional level of some individuals, meaning that there is another very important (and complex) clarification if we continue to answer the above-mentioned crucial question.

It is not hand-work that is needed, not exactly hand-work. A natural and traditional overall image of log houses, a clear and understandable appearance, a clean and high-quality performance is needed. There is a need for a variety of log sizes and a natural and unique combination of these logs, a need for correct, accurate and authentic corner bindings, a need for laconic shapes, traditional structures, and as unique decorations as possible. Namely, one must be able to feel the value of each log house, its antique essence, its unquestionable naturalness and calmness. And there is definitely a need for a special, exclusive log house, one that is above the mass produced ones. Customized, with its own character. And it is imperative that everything in a log house should be of superior quality, accurate, of high quality, beautiful, unforced and non-pretentious, preferably classic.

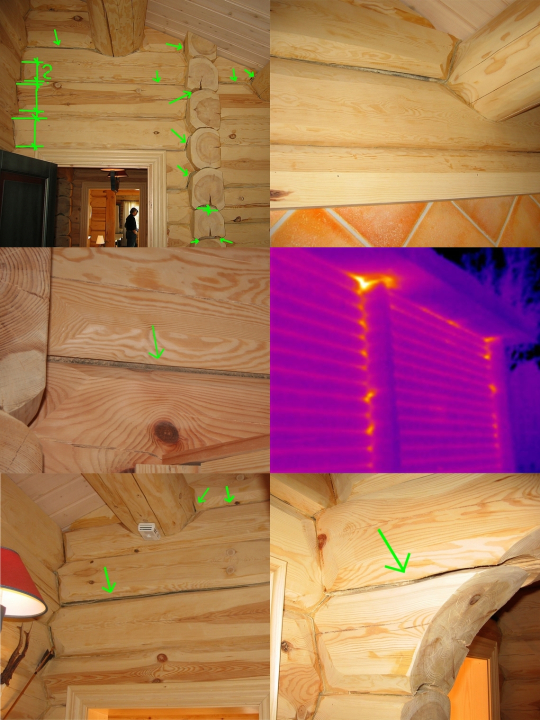

Log building assembly progress, near Zolva lake, Latvia. A much more modern overall image, bolder constructions, as well as the ascetic log profile #3.

A log house must be thought out spatially and from a design point of view, it should be functional, however, at the same time it also must be peaceful and unexaggerated, ascetic, non-obtrusive, aesthetic, with harmonized colors, made from real solid wood, with a beautiful texture and aroma, with good growth rings and of good origin. We could continue adding to this list on and on… In other words, there must be everything you can truly rejoice in, so that all this beauty can without doubt and with pride be demonstrated to all those around you. In other words, the Norwegians’ list of wishes and demands is much longer than that of Swedish and Finnish colleagues, and the flight of thought is also considerably higher, at least in this area. It has been rooted so deeply into the genes of the people, it lies deep in their blood.

So if the reference mentioned in the previous paragraph, this long list of wishes, is more or less realized in life, then it is more or less clear that the work has been completed well enough. But how much of the above would be the merits of the modern “hand-work”? What are the unquestionable competencies, abilities and technical capacity? Sure, hand-work practices offer to create log stacks of different shapes and sizes, but can it truly provide everything else as well? But perhaps it is hand-work that actually threatens and damages all of this? When it comes to today’s “hand-work”, the answer, more likely, is “yes”.

It should also be taken into account that the border separating the client’s enthusiasm from frustration tends to be extremely fragile and unpredictable, and even the slightest detail can damage everything. Like a drop of tar in a jar of honey. And yet, no matter the intensity of the clients’ attention, no matter how high their expectations are, Norwegians are willing to put up with so many troublesome things, to write off so many hurtful things with the specifics of hand-work, despite it all. Because no other option exists. Alright, but in the name of what? Just to be able to realize their amazing ideas and dreams, one’s soul is put into log houses. There is no doubt about this and, oh, dear highly esteemed “manufacturers”, this fact must be handled very, very carefully. This must be particularly taken into consideration, and in any case, should not be used.

Restaurant building in Amatciems – a project cherished by the owner, a well-known place in Latvia – rehabilitation, the art of cooking, jobs, etc.

Alright, back to the ground. Be it as it is, but the demand for this type of log houses is still significant. Simply put, the dominant part of log house purchasers does not know anything about and have not yet heard of our great (which it has been for a long time now, specifically made for them) product and its qualities. About our alternative to all these problems and insecurities, our alternative to the “hand-work” which finds itself in a state of degradation, our alternative in the form of ultra-modern production. We hope that we still have the time to remediate the situation, to fill in the gaps of your unawareness and unfamiliarity. In all honesty, we also expect that this will give us some additional opportunities to resolve the remaining issues related to product development even quicker, and to meet the expectations that have been placed on us all the more so. Your expectations. A longer derogation will now follow, since we believe that it is important to pass on the following detail for your assessment.

In the past twenty or more years, absolutely everyone has had the chance to participate in remedying the situation log houses have been and are in now. Historically, there has been a very favorable market situation, as well as generous working time, plus, all market players have had more or less the same opportunities. Therefore, there was absolutely nothing in the way of advancing processing techniques and strengthening production, however, it would certainly require some form of effort. But is it not worth trying if even for the sake of stability and a peace of mind? Even the direction of development did not have to be invented anew, since it was precisely expressed through the wishes and taste of the clients.

We must respect old traditions, hold on to authentic structures and ensure a quality befitting the modern times.

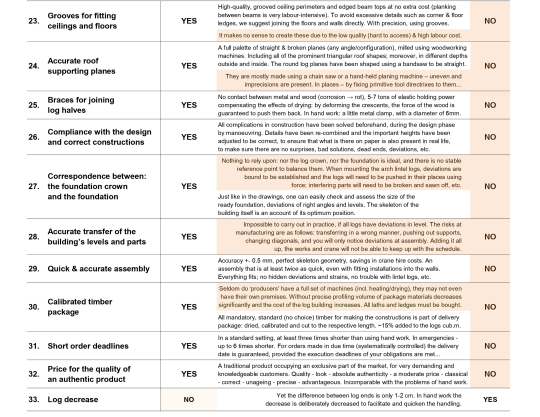

Fragments of drawings from Ervins Poga (member of the board) 1996 university diploma thesis in woodworking specialty. Instruction on the creation of corner joints and log structures in an effort to systematize manual operations.

However, as it seems, almost nobody else wishes to engage in such labor-intensive activities. At least we guessed so, or, perhaps, we are the only exception. Yes, but almost everyone boasts with their success in conquering the market and the rather questionable craftsmanship. Unfortunately, but through all these years so far nothing has been heard about the development of the product and production in the direction indicated and requested by the buyers, nothing has been heard about at least somewhat meaningful measures and successes taken towards improving quality. Have you heard of this before?

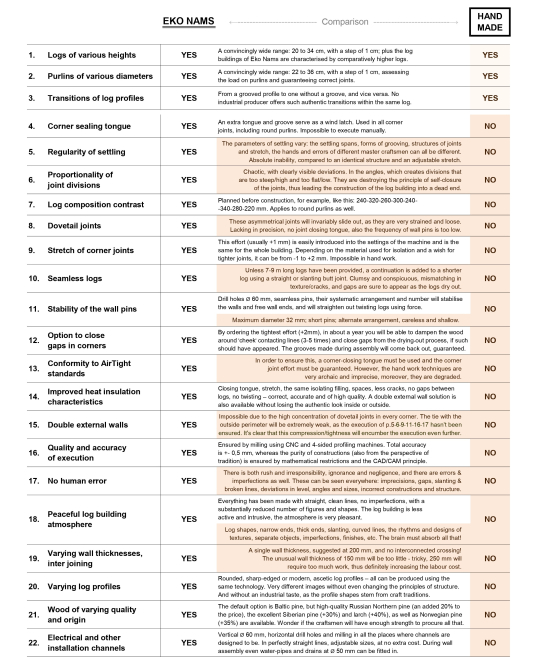

|

By the way. One exception has recently reared its head (at the end of 2019). The company which had been purchasing log house frames from us for 20 years. The company which was once our only distributor in Norway. The company that was closest to us and was able to analyze and copy everything regarding the product. The company which secretly did so, and now it is in a rush to build its own factory by copying our technology to the maximum. This company also has a name, of course — Østlaft AS. The proposed level of the product’s complexity, however, significantly falls behind, but that is a story for another time.

Assembly of the office building of Østlaft AS in 2008. Rudshøgda, Norway. |

You have not? This is not surprising because quite the opposite has happened by gradually ensuring that our company is in a situation where we have practically no noteworthy competitors on the market, and none such will appear in the near future. It is completely clear that all these “hand-work” producers or manufacturers will never pass the level of artisan producers. This is because, instead of sorting things, the minds of our respected competitors are so overwhelmed with conquering the market, with profit and their own arrogance. Was there no interest, not enough motivation? Was there no faith, was it not realistic, did it not make sense, was it not interesting, was there no time, no energy? Yes, it is unmistakably much easier to rest on your laurels, and to cultivate a rather unprofessional attitude for more than twenty years, to say the least. Alright, excuse us, but how do these stuck-ups dare to shamelessly deceive people and claim that log houses are their calling? How do they dare to be lazy for years on end and to not lift a finger for the sake of this product? Despite being aware of the fact that:

- They themselves are directly dependent on log house related revenue, on the flow of log house construction orders.

- So many customers still have to completely hopelessly and completely unnecessarily deal with the quality problems and mistakes made by these stuck-ups.

- Their clients have overpaid them so much and so uselessly.

For your information, we introduced the hardest task of getting our production process in order, the “universal or parametrically distributed principle of creation of the standard joint”, in real life (our production) in less than a year. Meaning, that it is not that long of a time period. And unlike most of the log house industry hotheads, our principle of operation and the understanding of business growth was, still is and always will be linked to its main goal — to organise everything relating to the product that we ourselves stand by and represent. So, to first get things in order for this unique niche product, instead of rushing to conquer various markets. Fine, at least not right away, and not necessarily.

Photo: Testing the first CNC-milled corner joint, under the supervision of a programmer, mechanical engineering and woodworking specialists – 22.04.2003.

We are sure you are aware of how log house companies as well love to boast with their achievements, how everyone is eager to use all the available marketing tools. What a significant market share they have already obtained, what impressive development dynamics they can publish on their websites, what place they have secured themselves in the market in terms of their size, and so on and so forth. Yes, but is it able to suppress all the doubt? Truly conquered — with what exactly? Does it somewhat describe the product itself? Therefore, let us once again emphasize the basic difference of our motivation, let us once again underline its fundamental character — not to conquer, but to pass order, regardless of how much time or money it may take.

Unfortunately, the financial and economical threats of quality, human attitude, marketing tricks, degradation of traditions are not the only threats there are… Unfortunately, modern standards and bureaucratic routines are also slowly but precisely tightening the loop around log houses. For example, the Guideline for European Technical Approval ETAG 012 “Log building kits”, 06.2002 and Council Directive 89/106/EEC. It is clear from this respected but theoretical document that only a few log house companies can meet the requirements set by the European Regulations. It is clear that “hand-work” companies are only capable of producing proof of origin and on rare occasions also a proof of conforming to some mystical standard. It is clear that they deliberately violate the law, because they surely do not intend to stop manufacturing and supplying bearing structures due to all these standards. However, it is unlikely that these log houses have passed strength class tests, the CE marking is unlikely to have been issued for these products, it is unlikely that any of these companies practices the overly expensive FPC (factory production control) certification, it is unlikely that any of them has carried out production model tests, but it is quite likely that hardly any of the companies offering log houses constructed using “hand-work” is willing to carry out continuous monitoring of the production process control through the competent inspection and certification bodies, particularly through accredited institutions. The rate chargeable for similar services for employees working in these organizations is only around EUR 200 per hour. With that, everything has been said — they simply cannot afford such exclusivities, nor is it their style to pay as much.

Be it as it is, but the standardization described above is hardly the right way to deal with log houses. This should definitely be done much more leniently and with some respect. Primarily, log houses must be assessed by their nature, and they should not be taken for granted. To be fair, we are too far lost in all these norms and standards; perhaps we have forgotten that a house is an environment in which we all live, relax, save our energy, find peace and shelter. We have also forgotten that it is also necessary to create a harmonious, healthy, human-friendly interior and outer environment in order to achieve maximum feeling of comfort In other words, it is important to appreciate the fact that a log house can surely provide it all, and uniquely at that, like no other building can, and this has been the case for centuries. Also, with the help of a house (a log house) and inside our home, we can express ourselves, our individuality, aesthetic values and taste, let everyone know about our view of the world, our social, cultural and ethnic belonging, our traditions, level of well-being and status in the society, meaning that we can showcase ourselves. Is it wise to push this industry into the corner like that? Is the goal to prevent people from expressing themselves, to prevent making use of the amazing qualities of log houses?

Log building from Siberian larch at the exhibition Norges varemesse, Lillestrøm, year 2004. The same log cabin that you could see in the thumbnail collage.

Of course, there are also other types of institutions, and they are not sleeping either. For example, the thermal resistance standards of buildings are regularly raised higher, as it is a good way to combat global warming, as they claim. Despite the fact that people are already dissatisfied with it, the employees of these technocratic institutions are forcing people to live in an unhealthy environment, in rooms that cannot be ventilated, offering to equip buildings with expensive air exchange systems, or recuperators as an alternative. These threats are also rapidly approaching log houses so loved by the Norwegians, the legislators are trying to raise the bar to an unprecedented height, but these “experts” do not even intend to deviate from their plans to introduce these exaggerated norms. They are persistent and insistent in their activities. This is hectic, because it seems that they have to justify their current and future point of existence by stubbornly resisting facts about the nature and behavior of wood without looking into human-made observations on the true thermal resistance of logs (especially about thermal inertia), without looking into the narratives of a pleasant living environment and through ignoring the fact that the symptoms of airway and other diseases disappear when living in log houses. Namely, if a house fails to meet the standards, even on paper, the house walls must be coated or covered with wadding. Otherwise it will not be possible to put it into operation, it will not be insured and they cannot go against the bank’s terms.

Forgive us, but there is at least one norm that they have planned, i.e. the density norm of a house, that log houses constructed by using hand-work will hardly ever be able to ensure. The houses are unlikely to be able to pass these Air Tight tests and will probably not fulfil all the other standards of the year 2020. However, if you think about it. Is it wrong that a house has a little, natural ventilation? Of course, no one is justifying log houses that have huge gaps, other heat leakage points and grave structural defects, but it is hardly pleasant to live in “a pot” of bacteria and people’s own (or other people’s) germs, it is hardly pleasant to form colonies of germs in an environment favorable to their culture medium with no air permeability. If such strict thermal and density requirements of a house are needed, will it not be possible to even open the windows from time to time? Perhaps it would be better to allow the installation of display-cases then?

Of course, the “miracles” of handwork blow and will blow everywhere. Of course, it is not possible to incorporate such a wind protection (Tongue and Groove) as in our log buildings.

|

By the way, one of our long-term business partners has performed a Blower Door test for one of our constructed and randomly selected log houses when the settling process of the log house was completed. And we (unfortunately, only we) found out that the new (recently proposed) standards have been met! That is good, but it is interesting that we were made aware of this fact in a rather unexpected way, in a completely different context. Namely, we received the results of tests carried out by the respective business partner, but, you will not believe this, along with the refusal to spread these news, because then, you see, everyone will run to buy log houses from us directly. The partner, though, does not refuse us, it even promises to inform everyone of this amazing fact if we grant it the status of an exclusive representative in the territory of Norway. Of course, we do not grant anything to such selfish “partners”. Those who play one of our product’s trump cards against us, who hold all the interested parties — the clients, the craftsmen, the craft masters and construction companies — in the dark, those who are actually bringing harm upon themselves. An astonishingly crude offer. By the way, the name of this company corresponds to the one in the previous reference. |

Thermography of EKO NAMS log house delivered in the Netherlands. As you can see, the problem is the doors and windows, not the log walls.

It must be finally understood that there is absolutely nothing wrong with wall logs and wood as a material; one should simply pay more attention to the quality of log house joints and log grooving, as well as to the heat transmission ratios of windows and outer doors, and it would be reasonable to pack as much insulation as possible in roofs. It must be understood that it is truly insane to force people to insulate log houses, thus causing them to create internal and external coatings, because in this way this whole event will irreparably lose all its meaning, and the risk of rot forming in the walls of the log house increases. And we are not trying to dramatize the situation at all — simply the time has come to ask ourselves a question. Will the oldest buildings man has invented — log houses — truly be subject to such shameful destruction in the end after they have already experienced a significant degradation of tradition and quality between the struggles of the modern world’s competition and costs? Will they be outlawed? With the power of self-made norms and laws, with their own “hands”? If you did not know this yet, the oldest log houses in Norway date back to the 17th century, but the famous pile building churches which have survived until today were built in the 12th century, and we are not talking about museums.

Photo from a log cabin ordered by Hovin Laft AS (Norway). A more modern, calm building design, and profiled logs instead of round roof purlins.

Anyway, Vilnis Kazāks, president of the Latvian Chamber of Crafts, confidently outlined the following future for wooden buildings, including log houses, in the aforementioned conference in Riga:

Many clients wish to enjoy the remarkable qualities of wooden houses — the unique air composition, natural wood surfaces, unique tactile sensations and so on, but they no longer wish to live in the traditional environment created by craftsmanship. Clients want perfectly smooth surfaces, spacious windows, modern communications and bolder structures. The solution is a new concept of wooden structure design — to preserve the historical achievements and involve a modern industrial production by shaping the “modern or industrial craftsmanship” with thus approach. Nothing is more constant than changeability, and the things that are willing to change can hope for a long usefulness and life.

The image of a wooden home has always had a special aura surrounding it, the subconscious mind recognizes this image, it creates a sense of security and pleasure. A new wooden house has every opportunity to preserve the imagery characteristic of certain regions as well. If we continuously develop the construction practices of wooden homes by retaining the best, historically proven ecological qualities and if we apply industry-specific methods and use products with modern technological guarantees, then wooden homes will, without doubt, become proof of an exceptionally good life”.

This was said 18 years ago. It seems that, in our case, his prophecies are going to be fulfilled.

And there is another, a modern, one could say, threat to quality. It is a universal and comprehensive tendency for the humanity to become desensitized, a tendency to develop a physical and mental atrophy. Namely… Have many kept the right and natural attitude toward any kind of work to be done? Do many remember lively, joyful, and imaginative working? Do many feel responsible or pride for the quality of any type of work they have done? From our 23-year long experience of recruiting staff, we can safely say that few employees possess that kind of attitude, it simply isn’t found in people’s genes, maybe in extremely rare occasions. And it cannot be taught through any courses or schools. Whether you have it in you or you do not.

For example, what does such a “careful” unloading of the delivered log house indicate? Tragically.

In the modern world of offices, people are often driven only by a desire to earn easy money, they are attracted by business moves that are as primitive as possible, and it is almost viewed as prestige to have to make minimum physical effort in your work. It is only logical that it is easier to simply buy and sell, let the Chinese work… either they will do the job or the machines will. So, who is still interested in this dawdling, fully completing things, to the best of their abilities, in a way that no one has to redo things after are done with them? And who is interested in thinking too much? When can one make any money then, and when can one live their life?

But it should be the case that we experience joy and satisfaction for the work we have done. That we experience it ourselves. It should be the case that the craftsman naturally strives to improve his mastery, that he yearns to learn more, that he wants to learn increasingly complex joints types and that he feels pride for every success of his craftsmanship. For true masters of a trade, their work is definitely also a hobby and a passion. And, actually, if you think about it… A person only performs truly well in what he sincerely enjoys doing, what fascinates him, where he can gain inspiration from, where he can express himself in a creative way. If that is not the case, then the work is viewed only as a form of suffering — as something compulsory, in the name of survival, working without any thought or willingness to do so.

Our programmer Girts Gaidels records with great interest all the nuances of log buildings, in a log house recently delivered to the client Norsk Laft AS.

Plus, it is absolutely clear that there is no literature available. Most of the training, if any, is primitive, without any reference materials and taking notes, so to speak, from the mouth of the craft master and into the worker’s ear. However, many things the master has said, if the worker does not really think about the meaning, may later be misunderstood, distorted, or deliberately simplified and unanimously accepted as the norm in the end. This verbally passed-on knowledge is collectively distorted without even realizing it. Or not heard in its entirety, or not fully outspoken, or, perhaps, said only in a superficial manner; but these things are being passed on in one way or another. Excuse me, but what books are we even talking about? And, actually, the craft master left a long time ago. And, actually, what is that? The houses are being built, and everyone is earning a profit. It is funny, but there are manufacturers who can present their ISO, UKAS and all sorts of other certificates.

Really? Is that the case of this product? As proof of unique craft-mastery? But rather as a unique marketing manipulation. When there is truly nothing else to say. Then one can dare to bluff with whatever possible, and at least boast with completely useless papers. In the situation log houses are in now? Funny, or, rather, tragic? In the case of hand-work, these certificates, by their very nature, are of a highly secondary nature; the routines and formalities suggested by institutions in such companies do not and will never work. Instead of catching a post-factum construction worker who is responsible for some defective part, would it not be better to start with a comprehensive renewal of knowledge on log houses, with the creation of systematized, well-structured and nuanced manufacturing instructions, with specific descriptions of product quality control and other measures? Would it not be better to implement large-scale measures to breathe life into and restore the way of becoming a craft master, to restore interest in the trade, to motivate young people to complete their disciple and journeymen training?

It would be better, much better, but these goals and tasks seem too utopian to anyone today. And, excuse us, but are there many people out there who care about it at all?

Such is the grooving of logs, sawing the ends of logs, “scraping” the window frame, vertical drilling and all the rest of ISO craftsmanship.

However, despite the apparent hopelessness and the low mood at the Riga log house conference, another Finnish delegate, Raimo Tikkanen from the Finnish Log House Tradition Centre, is working hard to resurrect this trade, even hoping for a renaissance and prosperity in this industry. The young gentleman proposes specific challenges to achieve this goal. Among other things, he stressed that,

It is necessary to ensure development in a number of areas — such as authorized log house design, further training of professionals by demanding high-quality diplomas, the creation of various open workshops for training purposes, certifying traditional log houses by creating a network of different experts. Construction and forge tools, as well as machinery must be developed further.”

So, what can be said here? We would like to wish him success, as well as to all the other enthusiasts and positively-minded people. Let him not hesitate for too long and get straight to grasping the nettle, as they say. It is unfortunate, but no one has heard anything about any of his achievements in the past 18 years.

Sincerely, Ervins Poga

By the way, in order for you not to think that someone is talking nonsense in these articles or, even worse, brainwashing you, we invite you to read the short two-page version of our brochure in the appendix. The brochure systematically, in essence, reveals all the nuances of our product, without missing any of the elements of log house structures which are valuable in regard to preserving tradition. Although this is how we lay out all our secrets in detail, we are not concerned at all about our future simply because we are not stagnant in our development. The path to implementing all of this in real life will be long and difficult enough for anyone.

By thoroughly studying all the small details of the construction of log joints described therein, you may come to the realization that the brochure can also be used as a handbook for any of our followers. At least, during the brochure creation process, everything was willingly revealed, with a relief that the matter had been resolved and that the product is in working order. In other words, nothing was hidden or concealed from you. Will the industry professionals acknowledge that our product is not necessarily an expression of some excessive nitpicking, but that it has been shaped in true respect for the wisdom and ancient traditions of our ancestors? We hope they do. Because by doing our best to preserve or even save these traditions, we also gave ourselves an additional task: to improve the quality of wood buildings, which can be characterized as quite specific, to create a harmonious, beautiful and finished product, to create a modern and lasting technology. And here comes the promised comparison table: