This joint is truly unique — on a global scale. The joint has a conical structure, moreover, the “saddle” or the “cheeks” are angularly oriented in two planes, therefore the joint has, both, a self-closing function upon the logs drying, as well as the ability to resist and prevent the logs from turning around its axis, namely, in tandem with the central plug. The logs are “saddled” not only convincingly, but also quite elegantly, and nothing more clever has been invented in regard to log houses. With a guarantee and absolutely safe.

Overall, the construction of a log house with Norwegian corner joints is an enormous, labor-intensive project. And it is good to mention that although the final version of these joints has truly been invented around 1860 in Norway, in the village of Lom, a similar joint type named Dalaknut originates from Dalarna in Sweden, and evidence of similar but simpler construction joints has also been found in the Rokua village in Finland. Besides, these are not the only places. Therefore, it would be more historically correct to call these corners of log houses, also known as log joint structures, “Scandinavian” without assigning copyright to any of the nations of said region. Photo: Log house from year 1613. Lom, Norway.

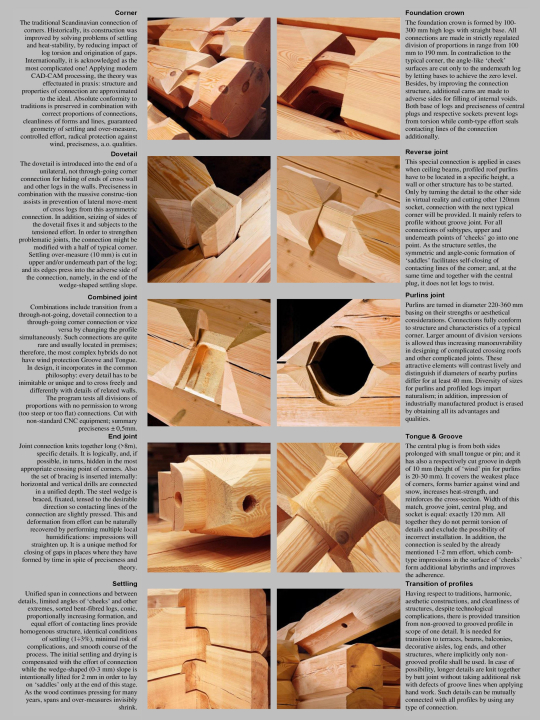

Alright, but let us devote some attention to a much more important fact. Namely, let us express gratitude to the ancient craft masters who, through the centuries, have managed to create and improve the structure of these corner joints step-by-step, and who even managed to not lose this knowledge to the ages. Yes, the harsh northern climate* has truly forced Scandinavians to figure out how to achieve maximum comfort in a log house, how to avoid stuffing wool in the corners of their houses so often, how to prevent the logs from turning around, how to ensure the building will settle, how to pass knowledge on to apprentices, how to optimize the sequence of creating joints, etc. And all of this was, in fact, successful. Moreover, it was perfect; the solution of the Scandinavian corner joint is absolutely laconic, and it can seem simple only to someone without sufficient knowledge on the topic. Here is photo of log-house corners from our Swedish representative’s demo house in the exhibition village of Norsborg near Stockholm.

However, all of this will only work well if excellent precision is applied while creating the “cheeks” of the joint and the central pin, if all the different craft masters will use a more or less of a similar approach, with balanced depth of the groove, with logs of more or less of a similar humidity. And one could wish that there are no mistakes, no rush and that all of these processes are controlled by at least one craft master or in the interests of a craft master. And, of course, the denser the joints after the logs have dried completely and the house has settled in its place, the less of an effect weather and rainfall will have on the log house, the harder it will be for the logs to start turning around, even for warped logs. Only loose joints allow the log rotation to be expressed in this way.

* – By the way, Siberia experiences an even harsher climate. They also have trees of excellent quality, and the people living there have a lot of respect and recognition for log houses. But I guess that is not enough. The people there have not even been able to improve their corner joints even by a little; even today, the joints are just as primitive as they were when it all began. This is because there are practically no joints, the roundness of the previous log is simply copied — another log, another empty (without a central plug) semi-circle. What is there to think about, what is there to invent anew? It is that easy — stuff moss, a lot of moss, everywhere where the wind blows through. The gruesome “artwork” of local masters can be seen in a collage, without comments.

Right, but let us return to the opening phrase of the article: construction of a log house with Norwegian corner joints is an enormous, labor-intensive project, because in the process of constructing such a building an enormous amount of work and an enormous number of man-hours must be devoted. Unfortunately, in most cases such a project would not be allocated a very high pay if we talk about the current situation regarding hand-work, and in the case of craftsmanship in general. And, all in all, is it not crazy that, even nowadays, many must carry out all processing operations with primitive hand or mechanized hand tools? With very simple and extremely inaccurate tools. An illustration of a sorrowful scene, see below.

It is clear that these corner joints have a very complex conical structure, many geometric shapes and elements. Yes, and that is why almost everyone feels that the task of full mechanization of the creation process of corner joints and log houses is extremely grandiose, too impossible, too complicated. It is hard to imagine, let us not talk about actually gathering the strength to undertake such a creative heroic work, a creative continuation of this saga. And where can one get such enormous funding, and how much creative effort will it take? How much time will it take? In how many years will it all pay off? Will these efforts ever pay off?

Saddles, top and bottom “cheeks”, settling slopes, the pin, the groove, settling spaces and other corner joints make it a lot harder to create a workbench or an assembly of machines that could produce such complex structures perfectly enough and with sufficient precision. Let us not even start discussing the technical and mechanical challenges in order to ensure the universality of such equipment. And how else to coordinate the management of such equipment? Even more so, the operation of such equipment must be linked to the building’s design program, which will also have to be produced from scratch. And what is more, the programming of this production process will definitely become much more complicated, especially because an industrial product of such parameters will have to be developed following all the hand-working traditions and design principles, in accordance with such uncompromising rules. So that the construction of a log house, the different types of corner joints and other structural elements, and, most importantly, their appearance, does not differ from works completed by hand.

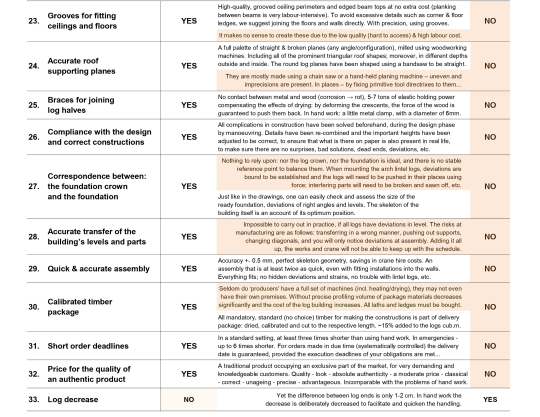

And in such a case, or EKO NAMS case, it is still we are talking about many different log heights, unique details, different combinations of joint (upper/bottom) proportions, different types of joints, profile transitions, and so on. Photo from the first exhibition house “Stabbur”, back in 2003, as well as a copy of the hypocritical advertising of our cooperation partner (that is, a simple seller).

But, oh, what a relief it is for everyone. It turns out that you can still mess around, that for the time being you can continue to not use your hands properly. For now, everyone — the customers, sellers, construction inspections, and even competitors — do not bother. Then, why not continue like this? And most importantly, the customers are not even aware of the excellent product alternatives that have been available for them for a while now. It is also clear that empty sentiments will be able to cover up quality problems, the fairytales of the aura of hand-work, the unique trees, their mastery will be able to woo the customers, they will be able to shove company awards, amount of houses built, increase in this number and other nonsense in everyone’s faces.

By the way, if one does not wish to lose this apparent peace forever, then all hand-work craft masters and team supervisors (controllers) should start taking care of a correct construction of corner joints and forcing the workers of this trade to carry out the creation of each detail correctly and precisely, they should also require the workers to comply with all the requirements and control every little detail and action. Not only the visible lines, on the outside, but also the internally joints must be perfect. Such that both the construction worker and the customer is happy to look at them. Therefore, we kindly ask, or rather, you should ask them all to pay attention to the following principles of creating joints. To mention only a few:

- it is necessary to very precisely adjust the contact lines of the joint’s “saddles”. And therefore, in order to ensure maximum joint quality, they must be repeatedly, as many times as necessary (in 99% of cases two times are enough), shaped. Please only perform this with an axe. And more, the same should be done for all joints — not too loosely and not too tightly;

- always remember to leave the correct or equal settling spaces between the pin of the joint and the groove, plus, by correcting and aligning it with the depth of the inter-log grooving or the so-called U-groove settling;

- it must also not be forgotten to cut sides of an appropriate angle and depth at the top of the joint, thus ensuring smooth settling of the joint. It is mandatory that all joints are closed with these conical edges, and this must be carried out by using semi-circular chisels;

- the logical intersections of the joint structure should be taken into account. However, complicated it may be, efforts must be made to ensure that these contact lines of the four “cheeks” meet at every corner of the joint. Meaning that they all must start or end at a single point.

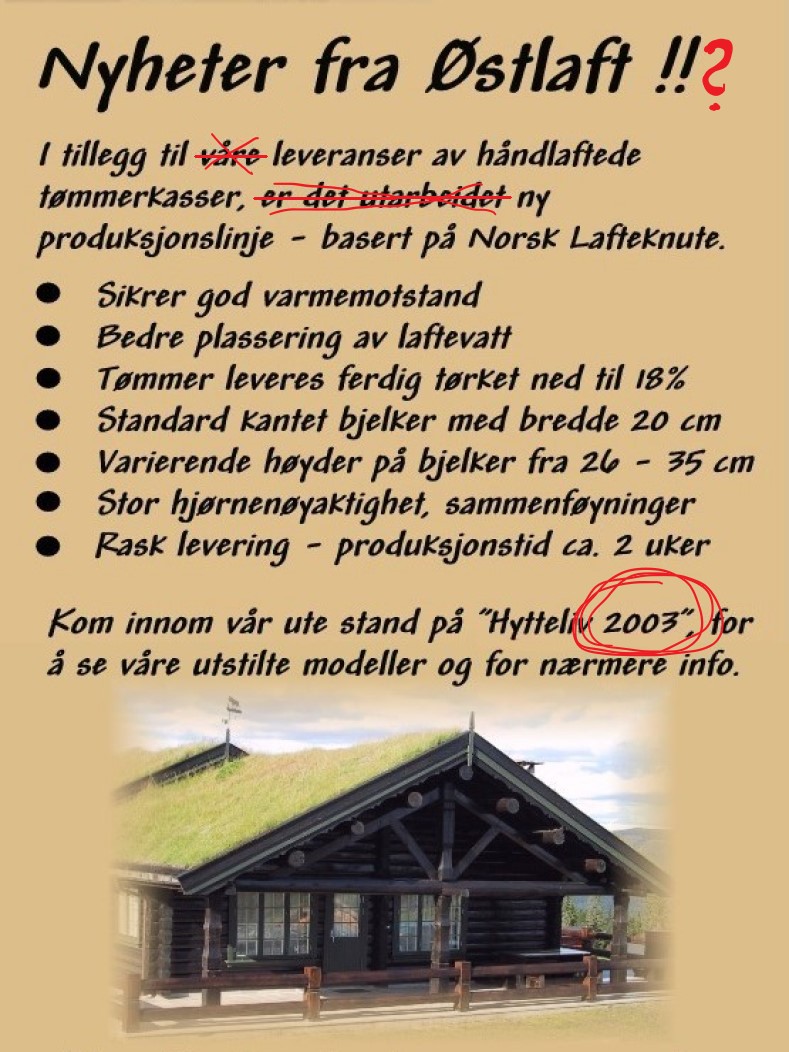

Not like in this picture of handmade defects, that is, in log formations which discredits the craft as much as possible:

Here is the view from below:

- aside from the fact that more or less similar dimensions of the cheeks should be maintained, the correct orientation and tipping angle should also be ensured. This will help to prevent the logs from turning. Of course, if you want to control this… In honor of this goal, the construction of the saddle joint has been significantly improved centuries ago. When compared to the Canadian corner joint “saddles”, Norwegian log joints were improved with “cheeks” in ages long forgotten and they have an angular placement in two planes and in two directions;

- disproportionately high and low log joints must be avoided, otherwise it not only threatens to lead other masters (and their supervisors) into a dead end, but creation of further joints may become practically impossible and the joints will turn out extremely distorted. Which means that slow and steady wins the race, or — measure thrice and cut once;

- the width of the grooving between logs must also not be too wide or too narrow. The fine shapes and curved lines of the U-groove must be created with a spokeshave. Please forget about your chainsaws, please put them aside.

Not only the visible lines, on the outside, but also internally corner joints must be perfect. Such that both the construction craftsmen and the customer is happy to look at them.

By the way, it would not be too wise to grind the “cheeks” of the corner joints with an angle grinder — such a vulgar technique. This is because by cutting the “cheeks” directly with an axe, the microstructure of the wood fiber will be locked, pressed and smoothened the most. The moisture within will have a harder time to damage the top layer of the wood, and dirt will no longer be able to penetrate the surfaces of the cuts so easily, the appearance will also be much cleaner, more respectable, and have the decorative footprint left by the cut of an axe. In turn, the angle grinder, with its rotating sandpaper at enormous speeds, will simply open the structure of the wood to the maximum.

Simply imagine this — it was not that long ago, a mere 20 years ago, when we could still afford to plane the logs, handmade by ourselves back then, with hand-operated planes, and spokeshave the roofing load-bearing logs. It is because of these natural, logical and aesthetic reasons, or quite the opposite of how it is usually done nowadays — with electric planes and angle grinders. And, in order not to increase collections of similar pictures…

Yes, it is easy to give out these truly valuable suggestions and advice, but it is not so easy to follow through with them and apply it in practice. At least not with the modern attitude everyone has or with the help of modern craftsmanship. And it is possible that even in very favorable working conditions, the hand-work will not yield such perfect results.

Besides, the work will not go as fast as it was hoped for, and it will not be as cheap to build a high-quality log house as it was initially planned. Moreover, there is no sense in exaggerating or overdoing things regarding quality, because moderation is achieved through the understanding that it will never be completely perfect however precisely and excessively the carpenter will try to shape all these corners and log joints. It is only logical that later on the tree dries and cracks form, that the tree may start to turn, that the joints may start to bend.

Yes, these are rather skeptical reflections, because the only thing that must become clear is that in order to create a beautiful and harmonious hand-constructed log house, all craft masters must do their work with a high degree of precision, without being rushed and with patience, as well as by carefully searching for and examining logs by applying appropriate knowledge, namely, predicting the behavior of logs in advance. Carpenters simply need to learn to juggle on the understanding of all these facts and situations, on the narrow border of reasonableness. However, unfortunately, it is not as simple, plus, it is very subjective and varied. And no matter how highly qualified or responsible any of the company’s craft masters are, it is important that other employees are equally responsible and sensible.

Such a “masters” races are organized in Estonia. Who will be the first to make a Norwegian corner joint? No comments.

But is it really possible today — to have such a united team of craft masters and such a leisurely work idyll? Unfortunately, the harsh reality of the modern world is that people are forced to work not for pleasure, but mainly to pay bills. Craft masters of log houses in Eastern Europe are not an exception either; they are also forced to rush their work, slaughtering remnants of any kind of joy for their work. Every single day they have to fight these logs, “bloody nails”, counting every single coin they earn. Crazy. And here are some questions that could lead onto some reflection: How many of these workers are craft masters, true craft masters? How many years of work or life does it take to become a craft master? How many craft master candidates do not endure the pressure, how many candidates are still in training, how many are simply there to have a good time, and how many of them do not even know what they wish to achieve in their life? Is it all (discussions about mastery) not extremely individual — age, temperament, character, upbringing, genetics, attitude?

To be more precise, the worst-case scenario should rather be considered, the fact that these teams are extremely varied, that there is a maximum risk of misinterpreting’s, misunderstandings, unawareness and irresponsibility. Maximum human error factor. By the way, many companies offering hand-work are boasting with the fact that they have at least five and sometimes even more craft master teams, and that only excellent craft masters are part of these teams. Is that really the case? That is rather suspicious since, at least, the Latvian Chamber of Crafts is saying the exact opposite. Namely, as far back as 15 years ago, it complained that people do not want to learn and get certified at all, that the meaning of the Chamber of Crafts is being devalued, that craftsmanship is also in decline, that knowledge, as well as the road to obtaining it, continues to disappear into nothingness.

Now, we will present a small example, firstly, on the accuracy and then on the loss of rationality.

So, after an element of the log house’s structure has been built, it has to be disassembled to transfer these elements in packages, for example, for a shipment to Norway. However, in the case of hand-work, the upper crown parts are almost always transferred elsewhere to continue working on, for example, the construction of the roof triangle or the construction of the second floor. For larger and more complex buildings, there may even be transmission of four different building levels, four transmission events. And so, something and almost always is damaged during these disassembly/ assembly processes, however, the main problem here is the probability that by transferring the logs, which are in the beginning of a new level, and by arranging them back together millimeters, or actually, centimeters will disappear here and there.

Each time a level is transferred this way — it can no longer provide an identical situation of logs, because when building a log house using hand-work, its straight-angle geometry is definitely changed, meaning that the diagonals of the upper crown of the house do not coincide with the diagonals of the lower crown of the house (in their base position). On the other hand, it is practically impossible to control the straight-angle geometry of a building in any other way than by ensuring that the diagonals of the building are equal. By the way, later on one of the many support blocks placed between the floor of the factory and these level-transferring logs twists out of its place or falls out, something is pushed into somewhere, something becomes deformed… Thus, as a result, larger and larger deviations in size and level are created forming gaps in joints and between log crowns. And it is quite clear that during the final assembly stage these detached and divided parts of the building will not be uniform and the bottom of the logs covering the apertures will certainly be imprecisely shaped or adjusted. Not very precise, that is lightly said, because that is going to be a difference between 2 cm and 4 cm. In short, corner joints and crowns will not only not fit together, but also create different unforeseen problems and gaps which should not be present in log houses. In the end, what are the “craft masters” left to do?

The only thing left to do will be to force these logs into the joints — to pull them in, to stuff them in, and to force them in with the help of tie straps. And what if the logs are not giving in? After that comes a lot of sweat — one must try to double, even triple the number of tie straps. And even if there’s is still a log going across the apertures which is not bending enough or not giving in? Then the last thing left to do is to cut, to grind something or remake something. Only in such a hideous way can the situation be improved or saved. Of course, the need to use one of these techniques is absolutely humiliating for a true craft master. A heavy blow to his professionalism.

Because afterwards he will surely have to assure both himself and the concerned customer that during the first winter that the house will have to endure the load of the snow will press together all these uncorrected and unrepairable gaps (without a doubt?). That is how (is it really?) it sometimes happens, since the snow loads fallen on the ground and on the roofs in Norway are quite impressive. However, such an unstable factor should not be blindly trusted. As a matter of principle, and never. Because, for example, under Latvian conditions, the settling of log houses here is less prominent.

So, for any technically and logically-minded person it is now more or less clear that an aggressive compression of log parts is taking place and that the accuracy of the transfer of the individual parts or levels of the hand-manufactured log house is simply tragic. The alternative would be to make the craft masters not separate log houses in parts and to continue to build it up to the top. In one go, provided that the height of the production facilities allows for this. However, this is too difficult and makes the weird construction process even more costly. In addition, the higher they go, the faster the pace, precision and quality of the work is reduced. What is more, the working conditions at such heights become dangerous to the human life.

All right, enough about this level transfer problem, it is just one of the problems related to precision. There has never been a shortage of quality hazards and various risk factors in the field of hand-work — some corner joint has been made too loose, with gaps, another joint is too tight, once carpenter tends to tip or turn the log to one side, another one tips or turns it to the other side, one tightening strap is tightened to one side, another — to a different side. One log is tightened stronger, another one has been tightened a little lighter, one end of the log is one way and the other one is different, in some parts the log settling grooves have been sawed deeper, in other parts they are shallower, some carpenters are used to doing things one way, the rest — quite differently.

Therefore, it is difficult or even impossible to describe the process of building a log house with the words coordinated and precise, and let alone call it modern and innovative. Not even such an “innovative”, life-threatening groove cutters will help…

It is hard to believe this, but attempts to babble trying to describe these processes as “innovative”, can even be experienced in real life. Well, what can be said here? It all happens in accordance with the best marketing traditions, along the lines of empty vessels make the most sound. By the way, we are now moving on to the subject of reasonableness and the loss of reason.

In our unique history of hand-work “manufacturing” we have witnessed almost every possible situation, including highly adjusted and tightened logs. Tightened with such force that a random worker, upon releasing a tie strap at one end of the log, can accidentally experience a workplace injury. The strap, now together with the log, can jump back just like a spring! Or this is the case when something has been made in a hurry and thus ends up being wrong and inaccurate; in such situations, employees often continue to rush even more without using common sense and they choose the most improper (the simplest and fastest) solution, they choose to barbarically tighten these logs trying to deform the timber by applying brute force. Other employees, of course, notice the authors of these “astounding” works, as well as the “examples” created and shown by them. Will they act the same? But, perhaps, they have not even seen anything different? And if they act correctly and precisely, will they also be able to make some kind of living out of it?

While continuing the irrational topic of log tightening, you must also definitely learn about and evaluate the following fact. Too often these “skillful” employees jump on the hand levers of these straps to achieve an even greater pushing force like circus acrobats, meaning that they press on them with their feet by applying all of their weight in this insane activity. The bravest individuals, on the other hand, even wedge an iron rod into the strap mechanisms to force the safety gears to jump to the next gap by using this lever. But what if one of these dangerous tricks, done in pursuit of higher productivity and wages, suddenly fails, what if the strap mechanism suddenly snaps? These workers are simply risking too much, because instead of receiving their salary, they risk receiving substantial bodily injuries. For your information, the cheapest tier straps can tighten logs with a force of 4 tonnes, but straps with twice and even three times the force are also available for purchase.

But just for your information, if people made these logs accurately in the very beginning of the construction process, they would not even have to be tightened. Then they would only have to be hit on the top a couple of times by using a special log hammer. It is the end of quite a heavy log with handles located on its sides, which leaves practically no trace of a blow since both materials involved in the process are made from wood. As is well known, wood perfectly absorbs and dampens blows; what is more, this hammer’s controlled free-fall (without any waste of effort) is the most powerful blow. Only this way, the work would be done reasonably.

We hate to even remember some scenes from our own hand-work related past. Scenes of how and with what hatred our dear “craft masters” are drubbing the logs using sledgehammers, which were strictly forbidden back then, how they crush the timber, moreover, in visible places unsuitable for such blows. How rushed they were, how irresponsible they hit the logs their eyes blaring wildly… Knowing full well that every one of these hits will create holes (gauges) in the contact lines or settling places of the log. Such memories are able to make someone feel sick. It is clear that these struggles — with people rushing, being irresponsible, extorting one another and with different problems regarding attitude — that they are all rather hopeless, even pointless, one could say. In particular, under such enormous pressure regarding pricing and other costs coming from customers, suppliers and even from the state. Useless, in this endless atmosphere of survival and competition, in this modern hamster wheel. Let us talk about these topics and atmospheres on a different day.

By the way, it is still quite often the case that another craft master has to finish work done by someone else, and it also happens that the responsible brigade leader falls sick and so on. And then, only much later, only during the disassembly all sorts of hidden defects are discovered. In other words, you cannot check everything and you cannot stand beside each worker, and even when they are seemingly caught, no worker will want to admit their fault anyway. However, craft masters must be aware that any inaccuracy and irresponsibility in work, including hand-work, is absolutely unacceptable, that it will undoubtedly cause unintended consequences, and these consequences will be felt by both themselves and other craft masters when creating further crowns of the log house.

And there is another very important quality requirement of log houses, in our opinion. Namely, the execution of log house elements should ensure that the spacing left for the settling process in the joints is as uniform as possible, and that also the spacing between logs is as even as possible and in a size aligned with previous spacing. This is extremely important in order to ensure an effortless settling of the assembled house, so that no accidental bumps interfere with the process, so that the situation in the joints and in the grooving between the logs is identical, so that identical settling gaps are left in all places.

Regrettably, it will not be as easy to implement in practice in the case of hand-work, because corner joints created by different craft masters in the log house mix with one another. So, one leaves one type of a settling reserve, while someone else may leave a larger or a smaller reserve; one stubbornly calculates a larger depth of the central pin, while a different carpenter calculates a shorter one; some even practice an absolutely illogical and chaotic style. This way someone always calculates a larger-sized gap, while someone else calculates a smaller size, and this chaos continues up until the creation of the joint itself, up until its processing. An extra millimetre here, an extra centimetre there… It often happens that some worker after a party on the night prior overcalculates everything, and the joint is “messed-up” right away. But what can you do? Things happen, people make mistakes; we are all simply humans.

The same-sized gaps, at least equal to most of the corner joints of a particular log crown, must also be ensured between logs, and in an equal size throughout the huge overall length of these grooves. For large-scale projects it could be at least a kilometer! And in real life, of course, things happen as they always do in real life — the groove kilometers are too deep in some places, and too shallow in others.

We strongly believe that, in most cases, this U groove is formed far too deep throughout its whole length. And it is very ill-considered because, as a result, the settling of the house or the loss of its height is unnecessarily and disproportionately large. Simply, in the case of hand-work it is much easier that way. A what is there to stress about, why should one fuss about the shape of the groove and those millimeters, it makes one’s head hurt. It is much easier to cut out a thorough, overly deep triangle with a chainsaw, or a rectangle which is the latest trend. So, the concern is about grooves with a depth of 3 cm and more. It is all about the madness of it all.

It seems that a lyrical deviation would befit here on the tools used in hand-work. In other words, this “U” groove must actually be created with a specially forged semicircle spokeshave, which must undoubtedly be equipped with a tempered (meaning, hard) blade, which, in turn, shall be regularly sharpened and maintained, and for a true craft master of hand-work this is a very precious and valuable tool. But, oh, only a few know how to sharpen their instruments, let alone in a way to make them perfectly sharp. Yes, as in many other trades, sharpening also requires talent, and above all — some patience. Yes, because not every empty-head can take up forging, sharpening or making log houses.

All right, so this groove must be made only with this perfectly sharp spokeshave, and not dangerously deep or too shallow in places, a log should not be cut with a chainsaw to then brutally, with a crowbar, break off the huge middle sections of the groove. What is even more sickening is that even after this violent behaviour, the craft masters do not take in their hands this specialized tool — a spokeshave — but the same old chainsaw to cut the edges of grooves by nervously pushing the chainsaw to the side. These fragile and fine edges, with a coarse and jittery chain of a saw. Alright, they cannot control a spokeshave, alright, they do not want and cannot feel the changing directions of the wood fiber, but do they really think that they are going to get somewhere faster with the saw? It is more likely that these fools have heard nothing at all about a spokeshave. And it looks like the rest of us will have to forget about the spokeshave permanently and for forever.

That is really surprising, because they even offer you a chance to see these embarrassing works in their own “promotional” videos, for example, on YouTube. It seems that the management of these companies does not really understand what they are doing, what they are showing, what they are presenting. Do they or the buyers or anyone does not realise how unworthy, primitive and vulgar this is? In addition, the work is not even performed with the relatively delicate electric saw, but rather with smoking chainsaws. Yes, that is the case because the electric saw has long been dropped, they see it as being too gentle, too fragile, and, above all, it lacks the power. Where is the precision, where are the natural lines — all of this is more than pathetic. Maybe the exhaust of the chainsaw is to blame, perhaps the smell has stunned and clouded the minds of these craft masters? But one thing is clear — words such as craft master and work should be written in quotation marks and in lowercase.

For comparison, the bottom picture already shows our profiled logs. For them, the groove is the same and precise everywhere. For the log houses we construct, the settling gap is currently 10 mm, however, we are planning to move to more shallow grooves in a little while. Because it is possible that by lowering the moisture content in logs to 12 % or by drying logs much more evenly in their cross-section we will be able to reduce this gap to a minimum. That is, up to 2 mm.

Yes, and do not expect that all these processing irregularities and the unevenness of these gaps will be squeezed or smoothened out by huge amounts of snow and ice which have accumulated on the already heavy roofs of the log house during winter. Yes, they help in some places and, of course, this huge mass pushes down the walls of logs, but for the same exact reason the ends of the logs are broken, especially starting from the lower crowns. It’s about more shallowly and decoratively shaped log ends, these unbelievably and foolishly shaped ends of the overhang logs.

And to be honest, for what purpose are the overly deep groove cuts made? For what reason have these huge, nightmarish triangles have been made, what purpose do they even serve, who needs all these chaotically made excavations? Is it easier that way? But is no one (including the end-buyers) truly following along? Because then it is much better to allow logs to settle on the back of the previous log as soon as possible. Besides, the first ones to burst are always these decorative edges of the overhang, the ones who have been placed the closest and most accurately in relation to the profile. Exactly the ones for which the craft masters have devoted their time so uselessly and tried so hard that, in the end, they have overdone it.

It is unbelievable. You see, in places where the log ends remain visible, there the masters, God knows why, are trying to make the groove more shallow and more coordinated with the other elements, copying the shape of the previous log. Perhaps they are aware of the dangers of the potential conflict, and they actually feel extremely ashamed to show such diggings to the customer. Some workers even exaggerate them by leaving no space for the settling process at all. As if they were willing to do good, they insert the profile with zero space left probably thinking, Oh, everything I did turned out so beautiful… But do they even think with their head? What is there to wonder about when these prop ends later burst and the sides of the logs open up? Is it not clear that the house’s self-mass (including the load of snow) is initially lying only on these short log ends, and not on the whole length of logs? All this sickening activity resembles a farce.

So, it is advisable or rather, it is mandatory that the settling gap is absolutely identical in all places, and it is actually harmful to make it larger than 15 mm. This observation especially applies to all those chaotic groove excavations at depths of 30 mm or more referred to above. Furthermore, these are especially harmful when combined with a masquerade of the “pretty” ends which, in its essence, is simply an idiotic creation. Of course, a lot of it also depends on how well these (many different) logs involved in manufacturing have been dried. How low is the humidity percentage in them actually? And above all, what is the distribution of moisture in the cross section of logs? What is the evenness of moisture, what is the difference between the moisture of the wood fiber of the sapwood and the core and so on? We will expand on this on another day.

Thus, based on everything that has been discussed here and without even looking for any particular culprit, the following thought or fact should enter the mind of any person. It is undeniable that construction companies and intermediaries in the Norwegian market (of course also due to the pricing pressure on their potential customers) have to take on a huge part of the blame for the loss of the quality of craftsmanship and its traditions, for enabling partial or total degradation of the industry. Because the pressure on manufacturers’ prices comes directly from customers, because it is the customers who squeeze the last breath out of hand-work companies, and thus from all the true and false craft masters. From those working in these companies who either make real effort conscientiously, or from those who only somehow fake their actions. Those who fake their knowledge about log houses, about the principles of their construction and structure, about the origins of log houses. Those who falsify the fact that they are also able to create the hand-made product which has been adorned with legends of marketing and which is mainly based on emotion. A niche product.

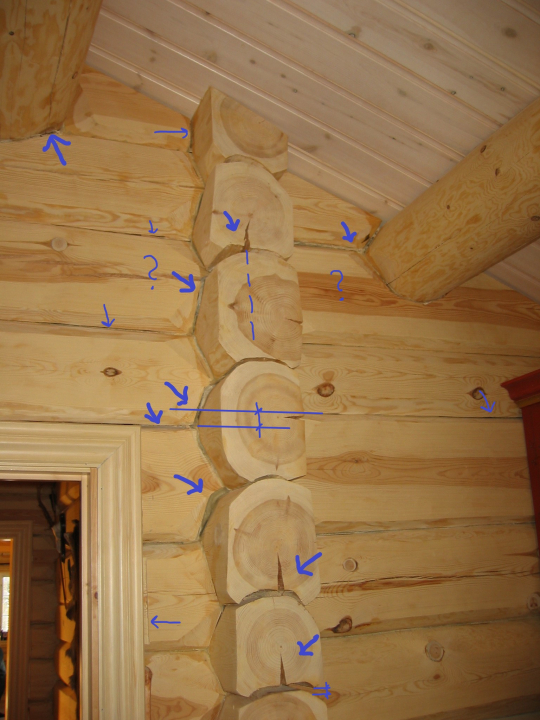

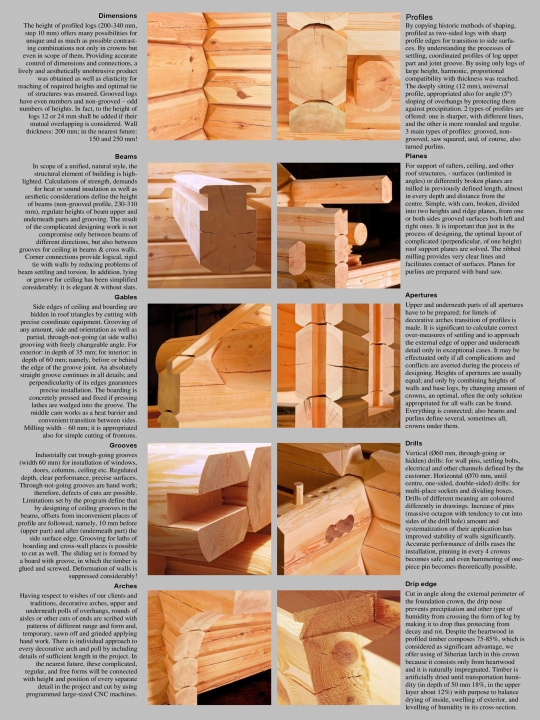

For your consolation, something beautiful at the end. A photo of a corner joint we produced. Finishing with a coniferous alcohol mixture “Woca”, Denmark.

We can only hope that true craft masters have zero interest in pursuing money and short work completion times if quality, tradition and precision must be ignored, we can only hope that they have no interest in damaging their attitude towards life and their inner convictions. We can only hope that they refuse to engage in this madness, that they have alternative job opportunities, that they do not have to break themselves down or violate the basic principles of their lives.

Sincerely, Ervins Poga

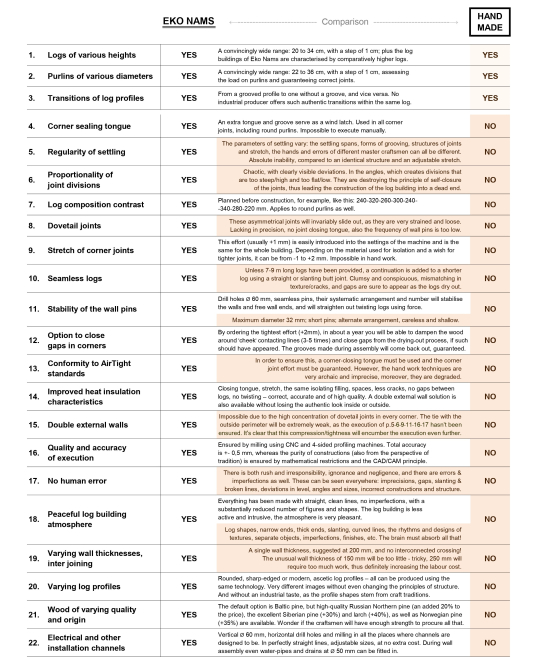

By the way, in order for you not to think that someone is talking nonsense in these articles or, even worse, brainwashing you, we invite you to read the short two-page version of our brochure in the appendix. The brochure systematically, in essence, reveals all the nuances of our product, without missing any of the elements of log house structures which are valuable in regard to preserving tradition. Although this is how we lay out all our secrets in detail, we are not concerned at all about our future simply because we are not stagnant in our development. The path to implementing all of this in real life will be long and difficult enough for anyone.

By thoroughly studying all the small details of the construction of log joints described therein, you may come to the realization that the brochure can also be used as a handbook for any of our followers. At least, during the brochure creation process, everything was willingly revealed, with a relief that the matter had been resolved and that the product is in working order. In other words, nothing was hidden or concealed from you. Will the industry professionals acknowledge that our product is not necessarily an expression of some excessive nitpicking, but that it has been shaped in true respect for the wisdom and ancient traditions of our ancestors? We hope they do. Because by doing our best to preserve or even save these traditions, we also gave ourselves an additional task: to improve the quality of wood buildings, which can be characterized as quite specific, to create a harmonious, beautiful and finished product, to create a modern and lasting technology. And here comes the promised comparison table: